Designed a robotic system to scale building façades and install solar panels without scaffolding. Developed full CAD assembly, integrated subsystems for the final assembly, and validated load-bearing safety through FEA and testing.

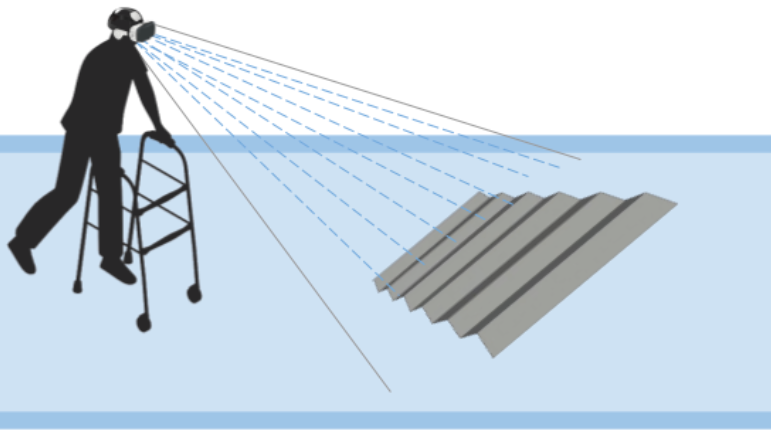

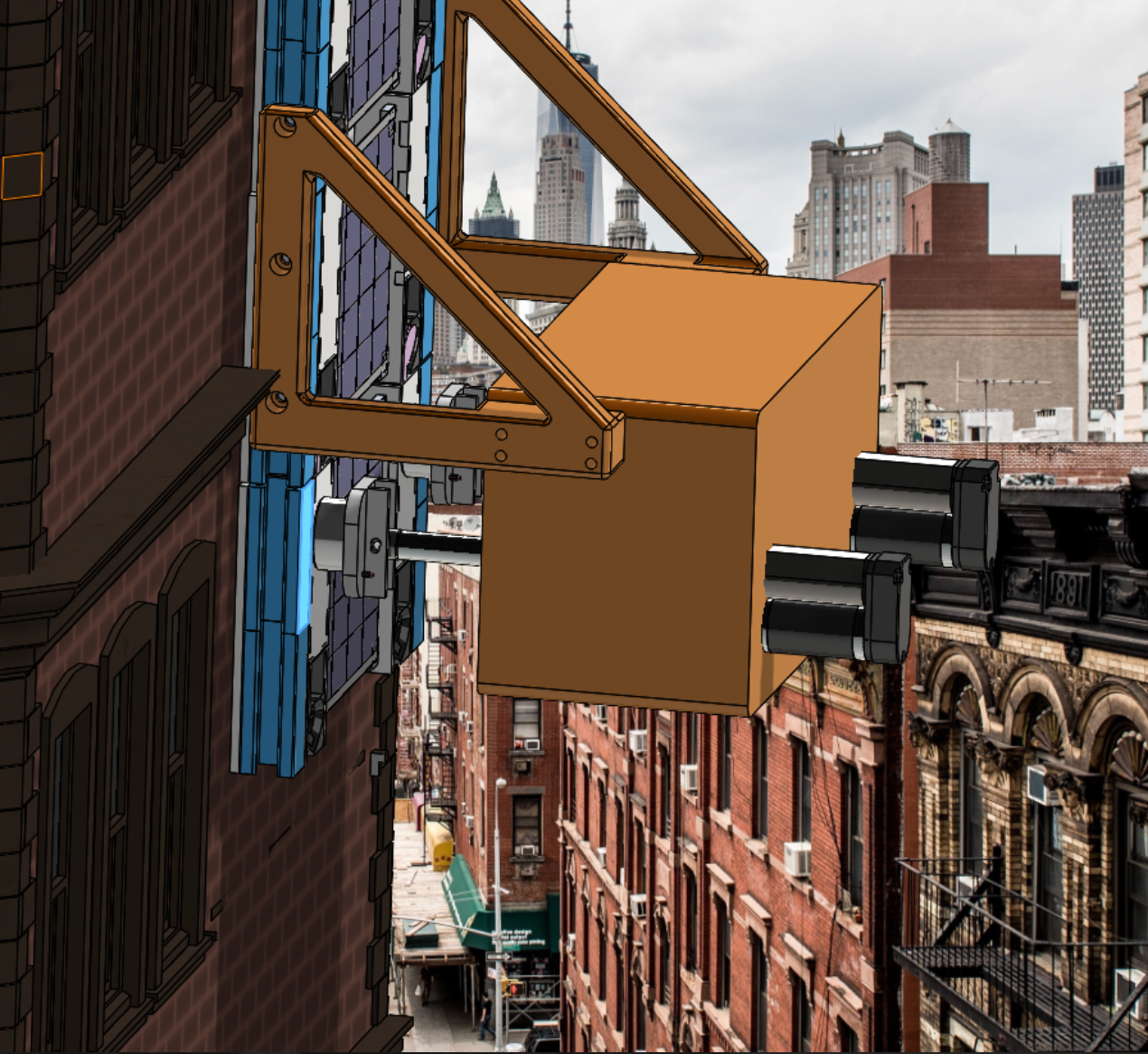

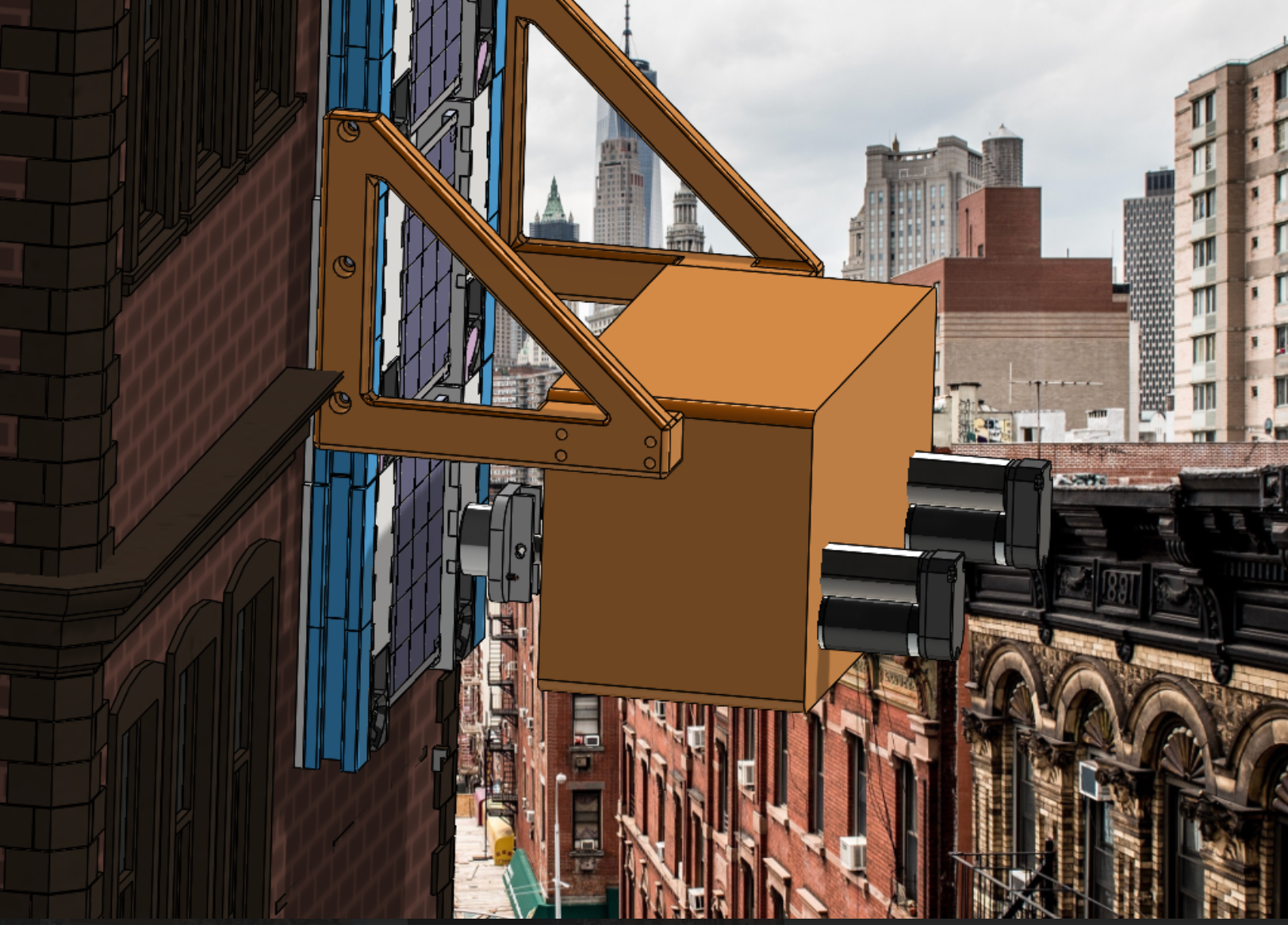

WallE is a solar-panel installing robot designed to simplify the adoption of renewable energy in dense urban environments. WallE scales building façades and installs modular solar panels with integrated mechanical and electrical interlocks, cutting installation from two steps to one. By installing solar panels without scaffolding, WallE reduces installation time, labor costs, and safety risks. Instead of sprawling solar farms, our vision was simple: go vertical. The project was inspired by NYC’s untapped vertical real estate and the need for safer, more cost-effective retrofits.

Clamp with attached winch is installed

First panel clicks into place

WallE begins installation

Arms snap panel into connectors

Extension arms retract

Repeat

My Role

• Owned chassis design, fabrication, and subsystem integration.

• Performed FEA + motion studies to validate load-bearing safety and motor sizing.

• Led prototyping within teaching-lab constraints by scaling system for realistic but testable operation.

WallE installing a solar panel

The Problem

• The price of photovoltaics has dropped 80% in the last decade, yet U.S. installation costs remain high.

• Rooftop solar space in cities like NYC is limited; façades represent untapped real estate.

• Current façade retrofits require scaffolding, which is dangerous, costly, and labor-intensive.

→ Goal: Enable cities and individuals to retrofit existing buildings with solar panels by reducing installation costs and time.

Design Exploration:

Needed a robotic system that could:

• Securely clamp to buildings.

• Carry and align solar panels.

• Is safe and manufacturable.

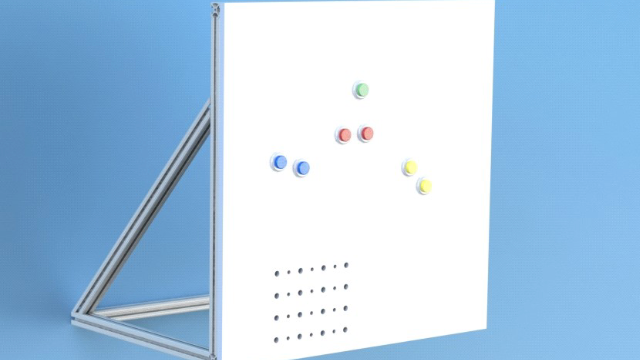

CAD render of early concept

We explored multiple support and alignment strategies with manufacturability and user feasibility in mind:

• Vacuum suction: unreliable on porous brick surfaces.

• Magnetic adhesion: limited use on masonry.

• Clamp + winch system (selected): reliable on brick, safe, manufacturable.

→ The chosen solution used a parapet clamp with winch-driven descent, ensuring secure load transfer and scalability across building types.

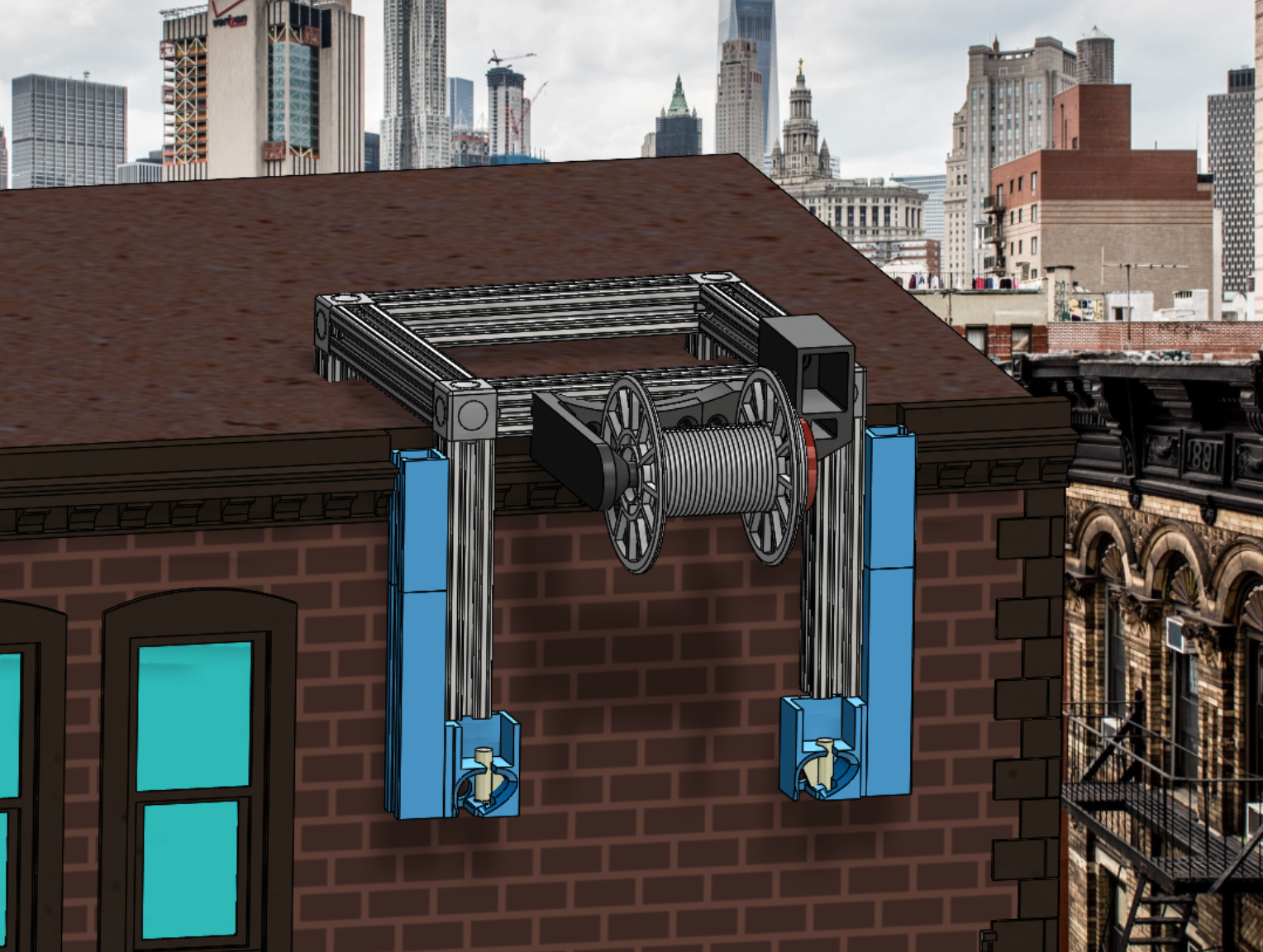

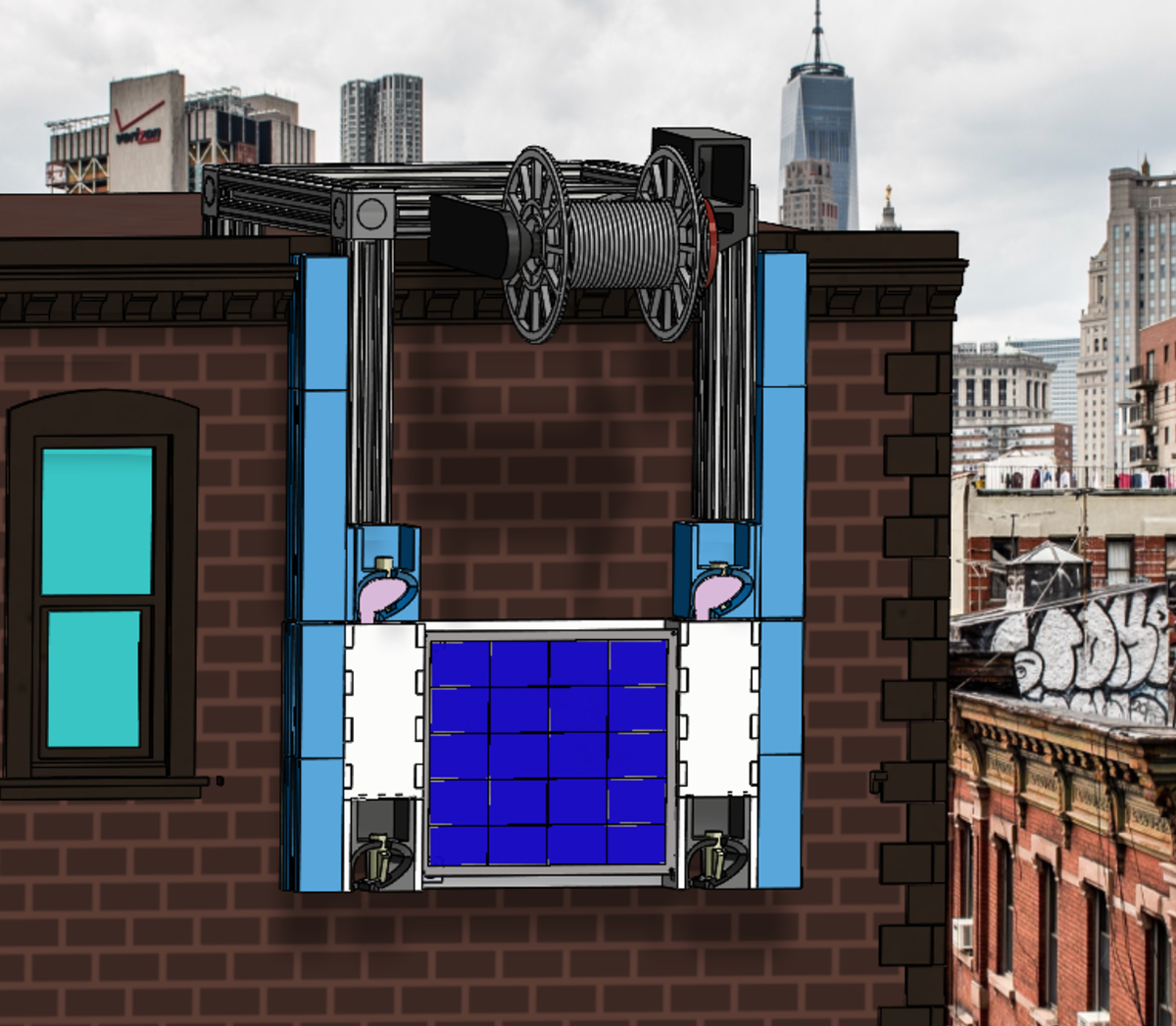

Updated CAD render of early concept

System Architecture

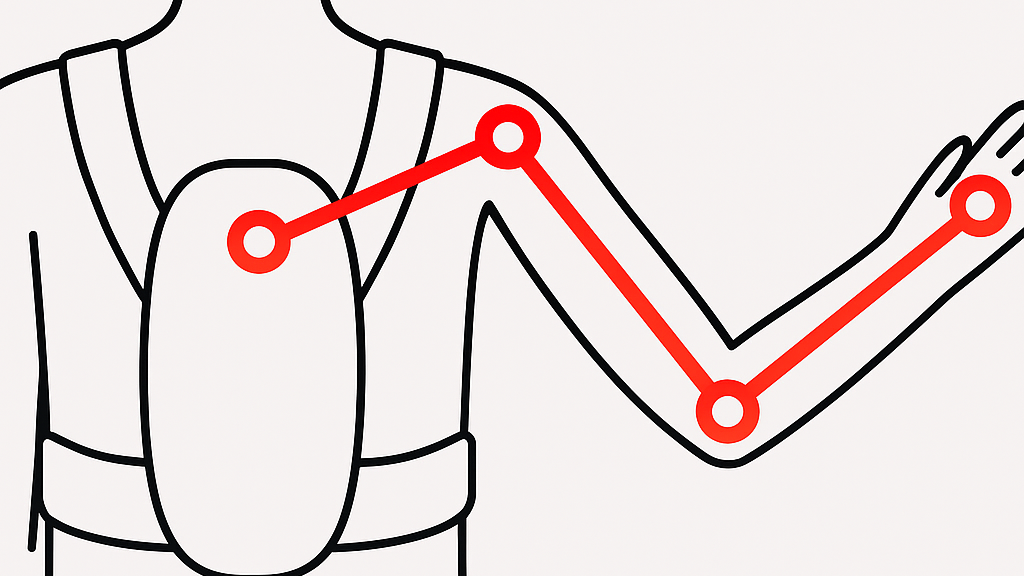

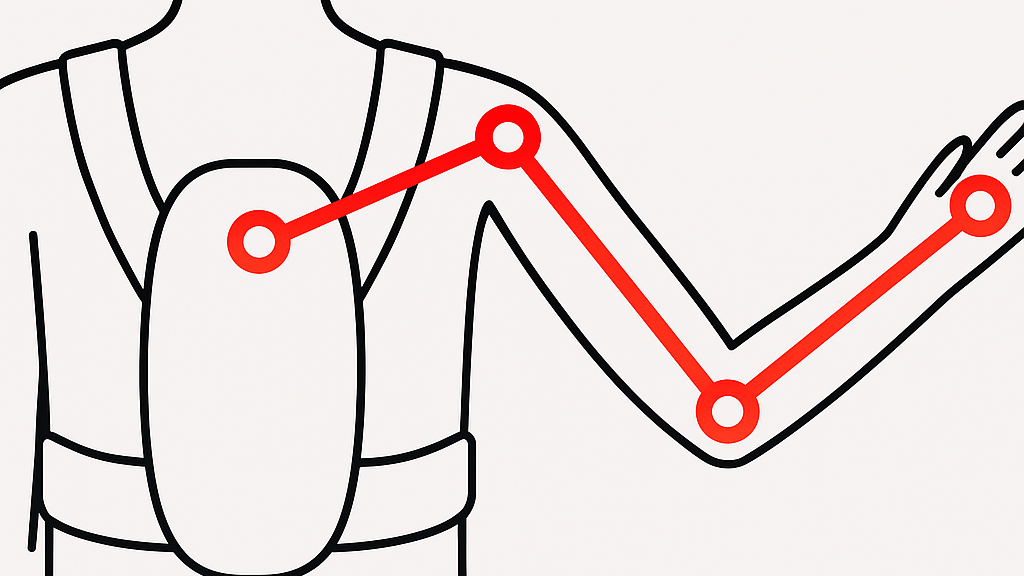

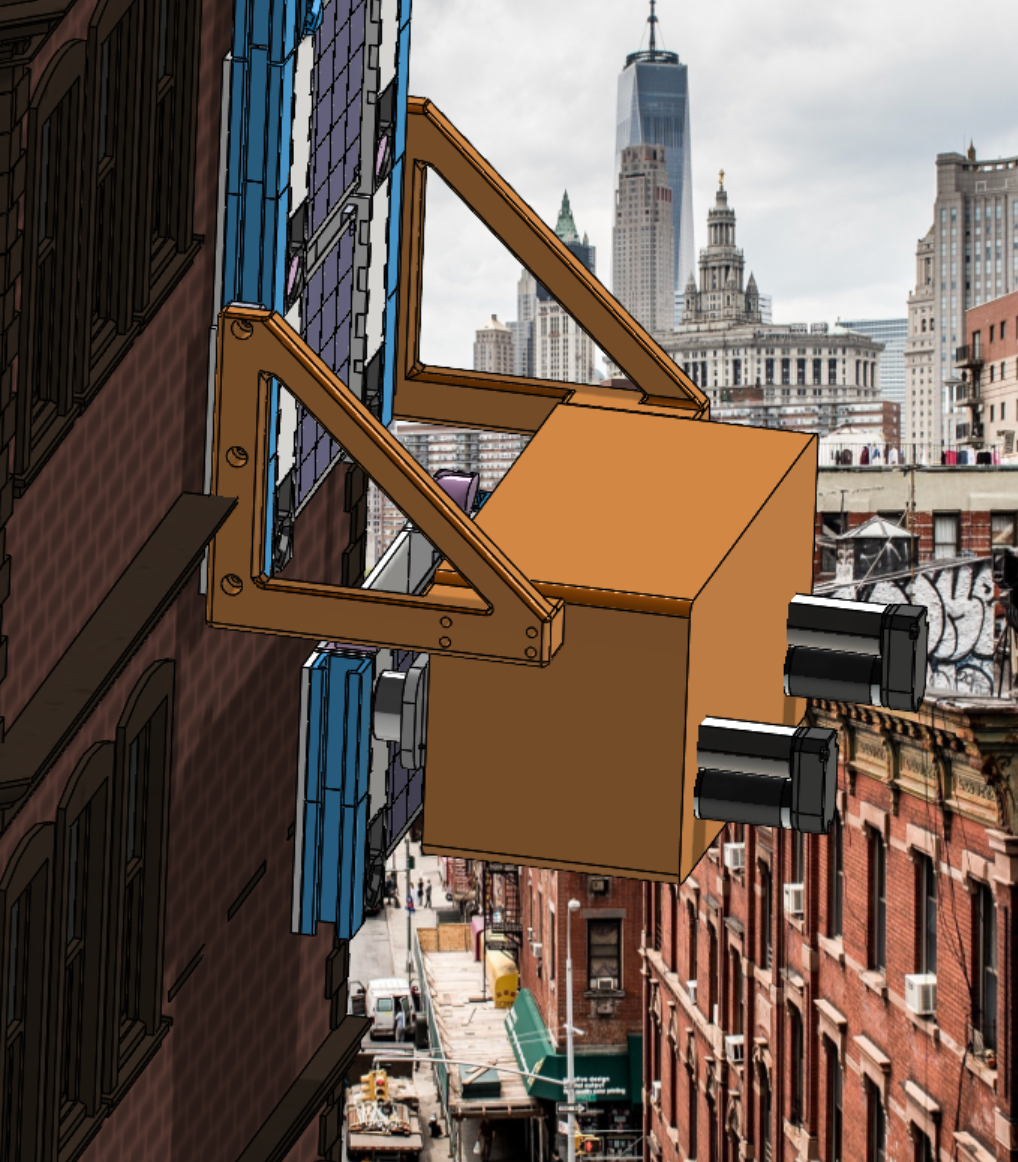

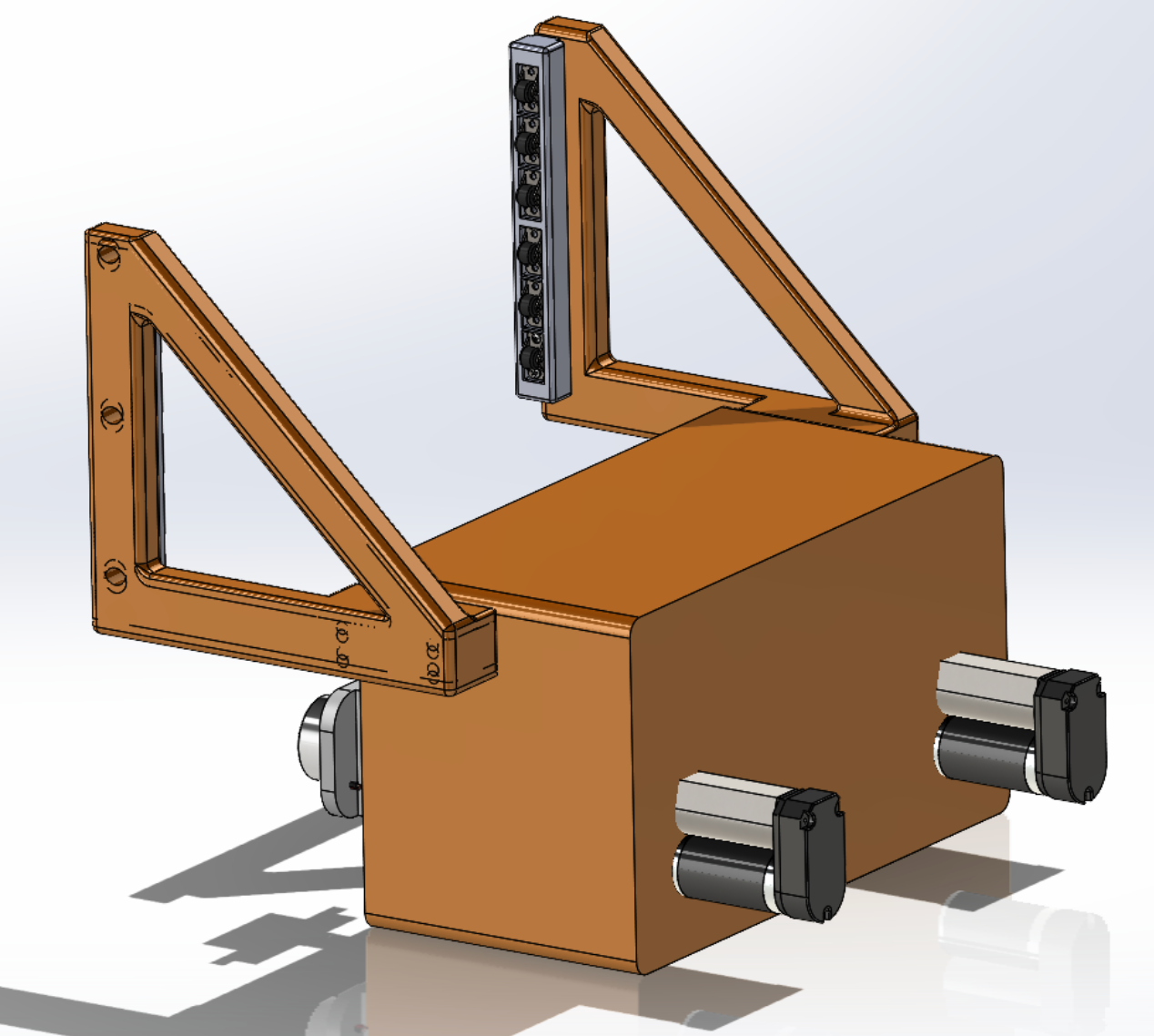

Chassis

• Housed internal components and carried solar panel frames.

• Side wheels interfaced with tracks integrated into the custom solar frames, ensuring alignment and reducing sway while eliminating the need for external rails or costly sensors.

• Extension arms with electromagnets gripped and aligned solar panel modules for installation.

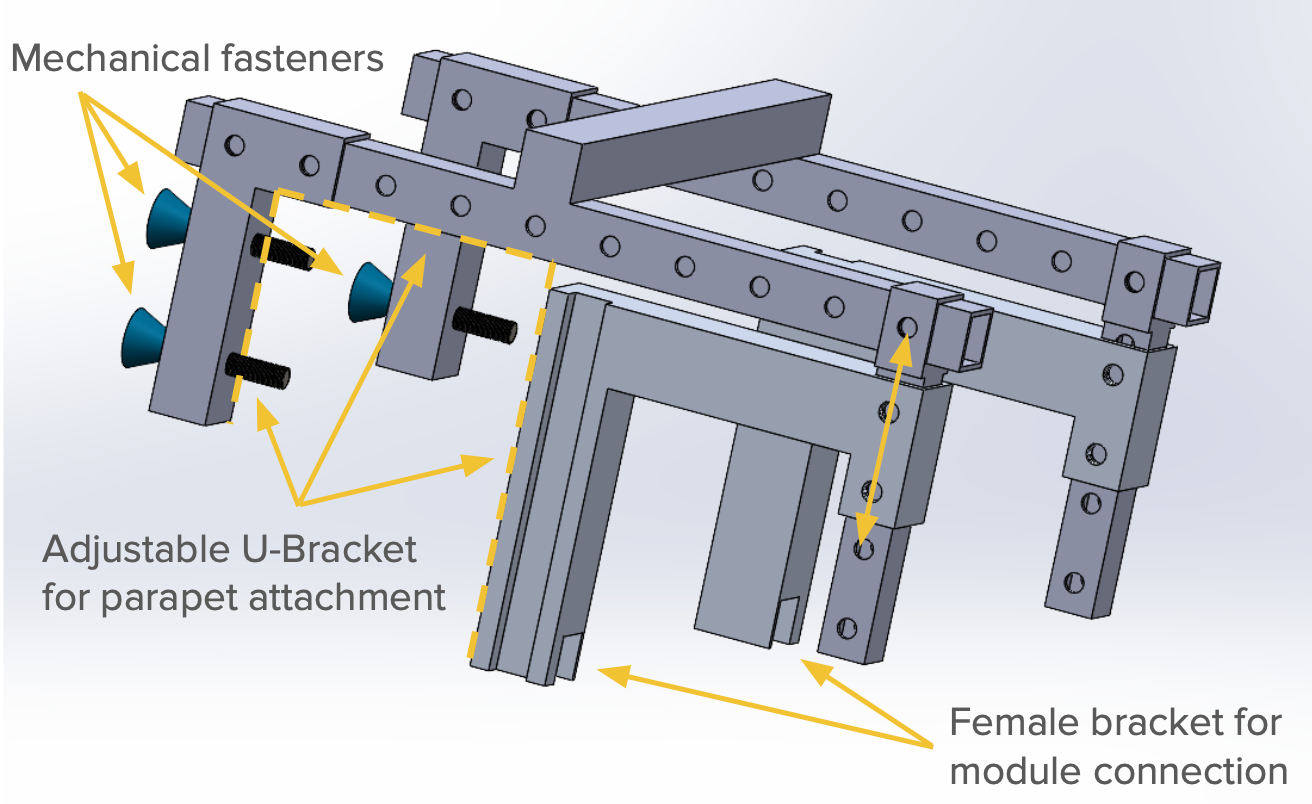

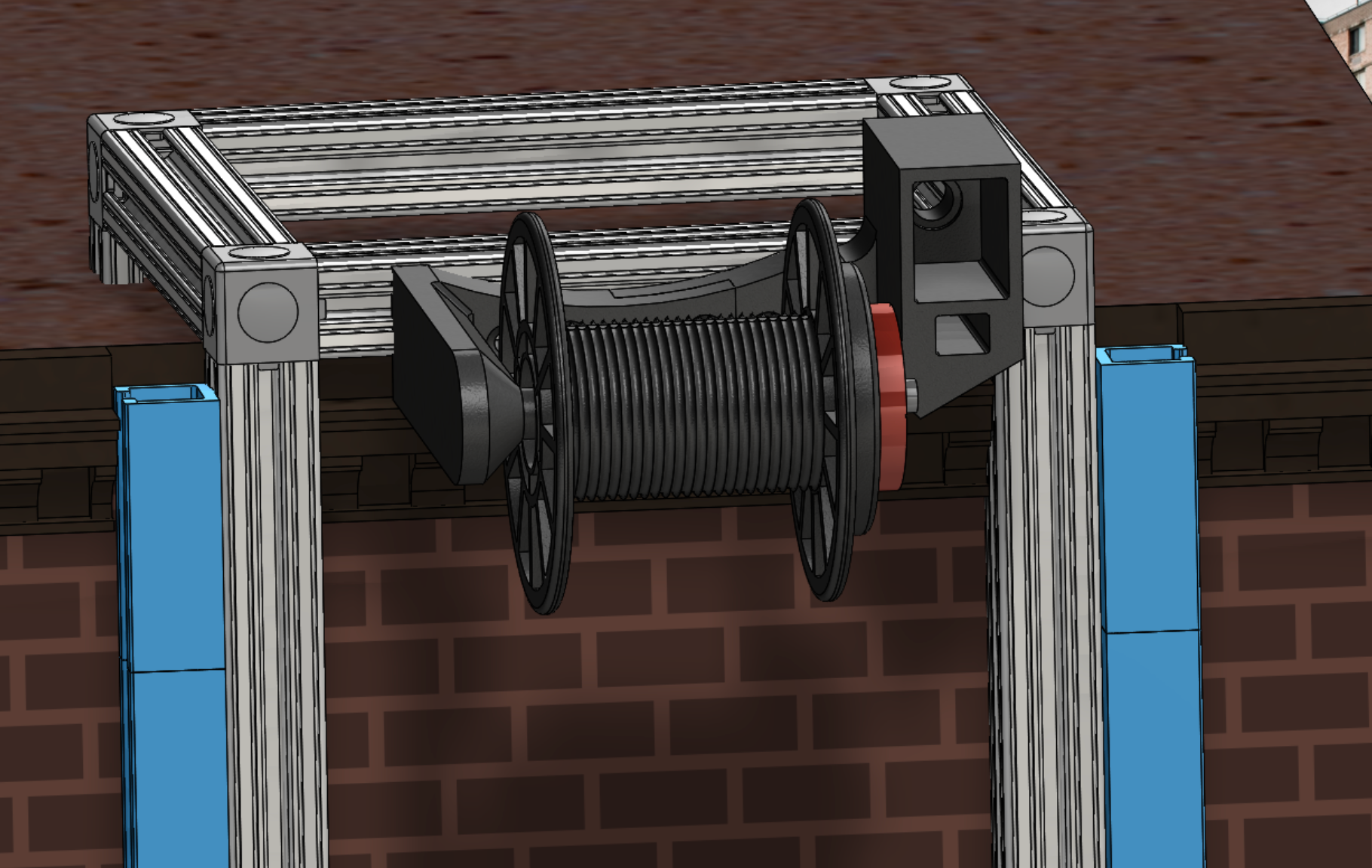

Clamp + Winch

• Adjustable U-bracket clamp for rooftop parapet anchoring.

• Primary load-bearing subsystem, machined from aluminum and validated with FEA.

• Integrated winch with 100:1 planetary gearbox enabled safe and controllable vertical motion.

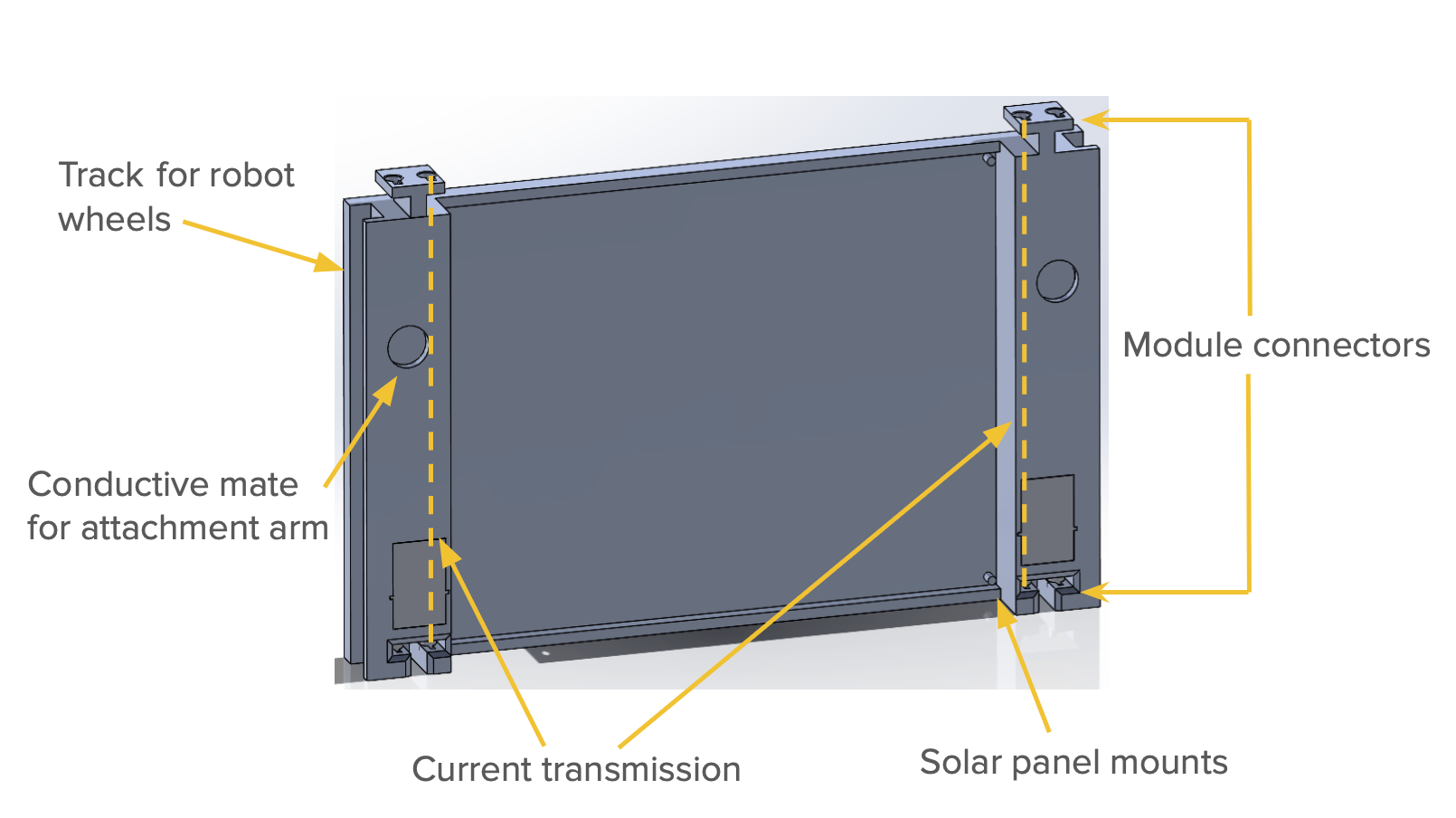

Solar Panel Frames

• Modular, custom-built frames enabled mechanical and electrical interlock in one step.

• Connectors secured frames together and wired panels in series during installation, simplifying the process from two steps (install + wire) to one.

• Tracks on both sides doubled as alignment guides for chassis wheels, mechanically constraining sway and ensuring alignment.

Chassis + Wheels

Universal Clamp

Winch (housed in clamp)

Solar Panel Frame

Close up of our frame and locking mechanism

Validation & Testing

• Aluminum Clamp FEA: Yield strength 7,999 psi vs. max Von Mises stress 804 psi → safe with 10× safety factor relative to total system load.

• Triangle Bracket FEA (Chassis alignment): Minor deformation predicted in PLA prototype, redesigned for no failure in integrated testing.

• Motion Study (Winch): Dynamic simulation confirmed motor torque and speed requirements under design weight; well within motor capability.

Clamp FEA

Impact

DFM/DFA: Reduced façade installation process from two steps to one step.

Scalability: Clamp + modular frame system adaptable across building types.

Safety & Cost: Removed scaffolding requirement; validated reliable load transfer.

User Need: Simplified urban solar retrofits for building owners, expanding adoption potential.

Reflection

WallE is more than a robot, it’s a concept for bringing scalable solar infrastructure to New York City by demonstrating how façade solar retrofits could be made safer, faster, and more affordable, unlocking vast new surface area for renewables in dense cities. By reducing scaffolding requirements and combining mechanical + electrical installation into one seamless step, the project offers a new model for sustainable energy expansion.

Testing!