This project challenged us to design, build, and test a powered mechanism capable of rapidly pressing arcade-style buttons under strict rules and scoring constraints. Our system used a four-bar linkage powered by a DC motor with closed-loop control to accurately position the end effector and maximize the score by hitting colored buttons in sequence, and a bonus green button for extra points.

My Role

Led a 6-person team through CNC machining and iterative design of linkage and transmission systems. Owned the design of the bonus-button actuator and collaborated on Arduino-based closed-loop control.

My Role

Led a 6-person team through CNC machining and iterative design of linkage and transmission systems. Owned the design of the bonus-button actuator and collaborated on Arduino-based closed-loop control.

Design Prompt

• Score points by pressing pairs of colored buttons (blue, red, yellow) as quickly and accurately as possible in one minute.

• Bonus green button offered extra points but introduced penalties if pressed at the wrong time.

Constraints

• Entire mechanism needs to be powered by a single 12V DC motor.

• End effector limited to a provided acrylic piece for pressing main buttons.

• Safety features (hard stops, limit switch, motor cutoff) required.

• Transmission and linkage must be designed for speed, accuracy, and repeatability.

Design Exploration

Our design process broke down into three subsystems:

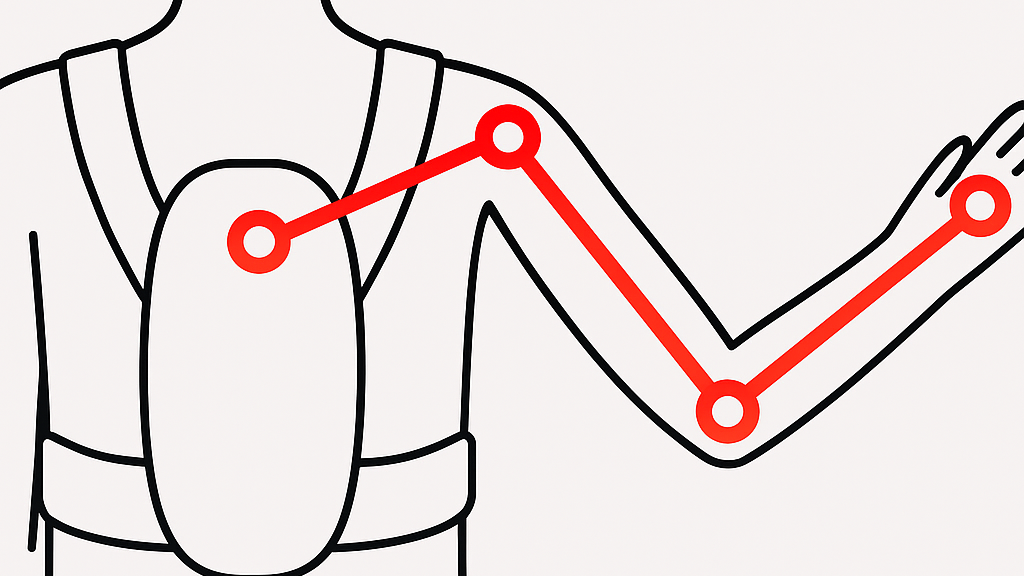

Linkage Motion Generation

• Explored multiple mechanism topologies before selecting a four-bar linkage for low inertia and precise repeatability.

• Integrated hard stops and limit switches to ensure safe, repeatable end-of-travel positions.

Energy Conversion/Transmission

• Applied inertia matching principles to size our transmission, minimizing travel time while maintaining accuracy.

• Iteratively refined linkage, base plate, and transmission layouts to reduce volume and maximize actuation speed.

Control & Safety

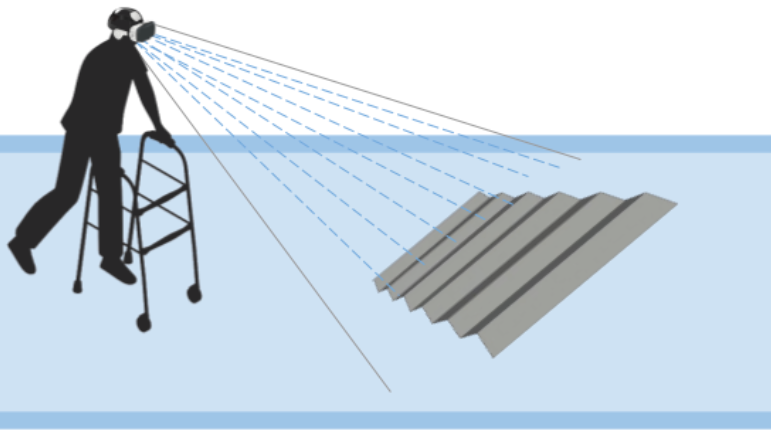

• Programmed closed-loop control in Arduino using a state machine + PID tuning for fast and accurate button targeting.

• Designed safety interlocks including a toggle cutoff switch and a limit switch for calibration.

Bonus Mechanism

Developed a compact clicker actuator for the green bonus button, which can be triggered to swing downwards to hit the buttons or upwards to hit the bonus button when signaled.

Validation

• CNC-machined components tested for tolerance-critical interfaces; linkage demonstrated reliable repeatability under high cycle counts.

• Transmission design validated with inertia calculations and physical testing under competitive conditions.

• Control system tuned through repeated trials to optimize scoring efficiency.

Results & Reflection

- Finished 3rd out of 15 teams for overall performance.

- Earned points for smallest volume and high button-press count.

The project highlighted the importance of systems integration across mechanical design, controls, and manufacturing. By combining linkage optimization, CNC fabrication, and closed-loop control, our team delivered a compact, reliable, and high-performing solution which showed me how iterative design and cross-disciplinary collaboration can achieve both speed and accuracy under real-world constraints.